Home » How does Spark Erosion work?

How Does Spark Erosion Machine Work in 2022?

This article is a detailed introduction for those who want to know and buy spark erosion machines, to help them understand the field of discharge machine faster. At the end, some recommendations of how to select a suitable CNC EDM Machine from Sammlite Machinery.

CHAPTER 1

Definiation Of Spark Erosion

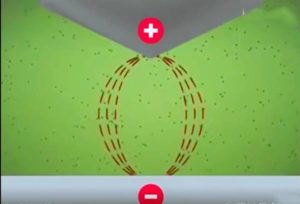

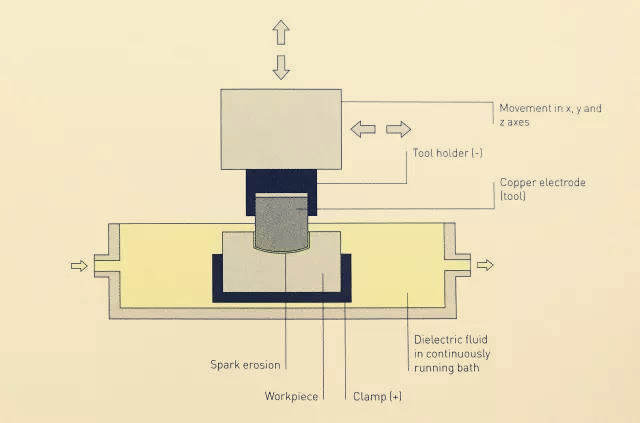

The principle of Spark Erosion machining process is to remove excess metal using electrical corrosion (pulsed spark discharge) between the tool and the workpiece, in order to achieve the desired size, shape and surface quality of the workpiece.

As shown in the figure, the workpiece and the electrodes are respectively connected to two electrodes of different polarities of the pulse power supply.

The Materials Needed For EDM Spark Erosion Machines

Electrode:

Electrodes are commonly used materials with good electrical conductivity, high melting point and easy processing, such as copper, graphite, copper-tungsten alloy and molybdenum. During the machining process, the electrode will be wearing off, but it is less than the amount of removal of the workpiece metal, and even close to no loss.

Below are electrode materials for each types of CNC spark erosion machine:

Die Sinking EDM: copper, graphite

WIre cut EDM: Brass Wire & Molybdenum Wire

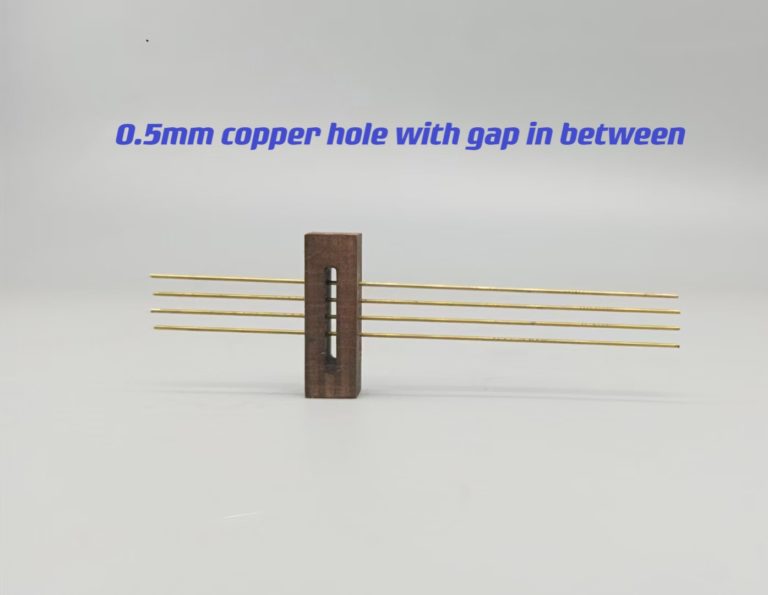

Drill EDM (Hole popper): Brass Electrode Tube & Red Copper Tube

Dielectric Liquid:

As a discharge medium, the working fluid also plays the role of cooling and chip removal during the machining process. Commonly used working fluids are mediums with low viscosity, high flash point and stable performance, such as kerosene, deionized water and emulsions.

Workpiece Materials Selection:

Selecting different workpiece materials according to the use of the workpiece, for example, according to different mold types. Cold die steel is generally used for spark erosion of dies. Hot die steel is generally used for electrical discharge of cavity molds. Taking aerospace industry as an example, it uses high temperature heat-resistant alloys, high chromium and high nickel alloys, titanium alloys and etc.

Clamping And Correction Of Workpiece:

Nowadays, 3R and Erowa tooling system are most common selecting. Because they are convenient and reliable, high repeat positioning accuracy, especially suitable for spark erosion mold production.

What Is Spark Erosion

When a pulse voltage is applied between the two electrodes, a proper gap is maintained between the workpiece and the electrode. Then dielectric between the workpiece and the tool electrode will be broken down to form a discharge channel.

Instantaneous high temperature is generated in the discharge channel, which melts and even vaporizes the material on the surface of the workpiece. As an results, it is also vaporizes the dielectric, which rapidly thermally expands at the discharge gap and explodes.

After the electrical discharge machining is over, the working fluid is restored to insulation. The pulse voltage acts on the workpiece and the electrode repeatedly. This process is repeated continuously, and the workpiece material is gradually eroded away.

The servo system continuously adjusts the relative position of the electrode and the workpiece. Automatically feeds it to ensure the normal operation of electrical dischage until the required parts are processed.

CHAPTER 2

Types Of EDM Spark Erosion Machine

Spark Erosion is the most widely used processing method in the electrical discharge industry.

According to the relative movement of the electrode and the workpiece, it can be roughly divided into CNC DIE SINKING EDM, High WIRE EDM CUTTTING SPEED EDM and SMALL HOLE DRILLING EDM MACHINE.

Among them, wire cutting processing accounts for 60% of EDM, and die sinking processing accounts for 30%. With the development of electrical processing technology, spark erosion processing has become a symbol of advanced technology, accurate cutting process.

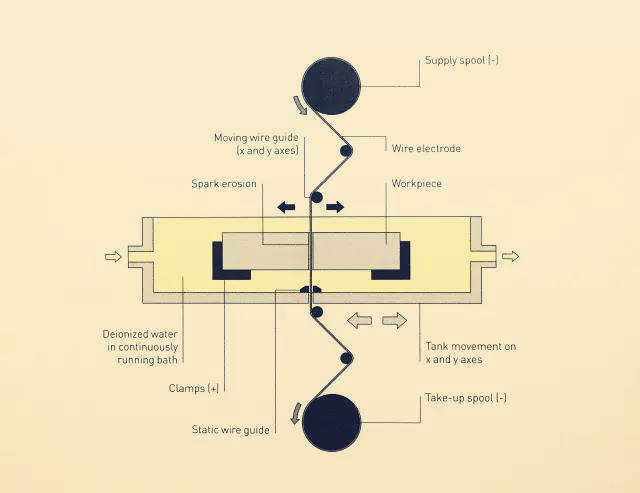

Wire EDM is divided into brass wire and molybdenum wire cut EDM. Generally, electrode wires with a diameter of 0.1mm~0.3mm are used to process straight-grained parts, which can be punch parts or die holes.

1. The electrode and the workpiece move simultaneously in two horizontal directions;

2. Cutting various dies and parts with ruled surface;

3. In cutting tools, precision small parts and special materials

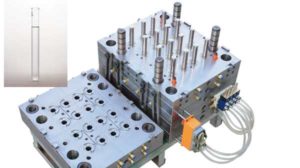

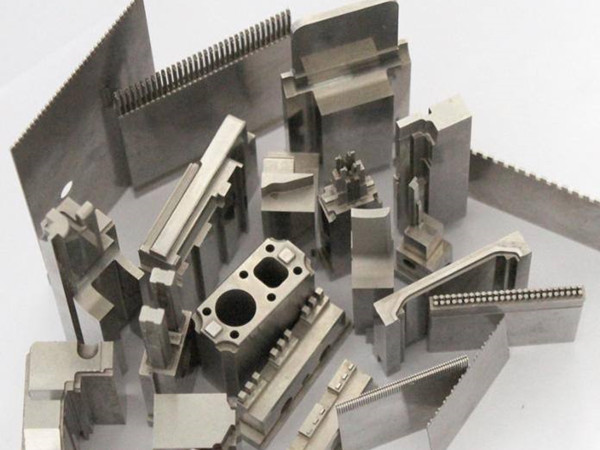

The tool electrode is usually a copper or graphite forming electrode, which can be any shape that can be produced, and the processed shape is the corresponding cavity.

1. There is only one relative axis movement between the tool and the workpiece

2. The tool is an electrode, which has the same cross-section and corresponding shape as the surface to be machined

3. Peneration processing: processing various punching dies, extrusion dies, powder metallurgy dies, various special-shaped holes and micro holes, etc.

4. Cavity processing: processing various types of cavity molds and various complex cavity parts

1. Use a thin tube of 0.3-3.0mm brass tube, and pour the high-pressure water-based working fluid into the tube;

2. The thin tube electrode rotates;

3. The perforation speed is very fast (30~60mm)

4. Wire cutting starting hole popper

5. Small holes with a large depth-to-diameter ratio, such as nozzles

CHAPTER 3

Advantage Of Spark Erosion Methods

1. Spark Erosion machining can process materials and complex shape workpieces that are difficult to cut by ordinary cutting methods.

2. The eroding process is hardly affected by heat, so the thermal shock layer can be reduced. Because of this the workpiece with high machining quality can be achieved.

3. No defects such as burrs and knife marks and grooves.

4. The electrode material does not need to be harder than the workpiece material, so it is easier to process and manufacture.

5. High security, the working fluid of wire cutting is non-flammable.

6. High machining accuracy Accuracy<0.008mm

7. CNC Die Sinking EDM has excellent surface finishing Ra<0.1um, no polishing required.

8. EDM can eliminate the vertical angle of the workpiece, no R angle.

CHAPTER 4

Spark Erosion Applications & Examples

Automobile Bumper by Die Sinking EDM

Punch Die & Holes by Wire Cut EDM

0.3mm Holes by CNC Drilling EDM (hole popper)

CHAPTER 5

Tips of Selecting CNC Spark Erosion Machine

1. Brand of EDM machine

Brands can also represent quality, so buying a spark machine also depends on the brand.

Recommended brands: Agie Charmiles, Sodick, Mistsubishi, Sammlite Machinery

2. History of Spark erosion machine manufacturing factory

The length of production history of the CNC EDM Machine manufacturing plant can tell how stable its products are.

3. Requirements for products

There are four main elements of CNC spark erosion machine performance: surface finish, electrode loss, processing speed, and processing accuracy.

4. The size of the processed product

Choose edm spark erosion machines with different stroke sizes according to the size of the product to be processed.

5. Processing technology

Different choices of EDM machining processes are also different.

Available in die sinking edm, wire cut edm and drilling edm (hole popper).

6. After-sales service capability

According to the importance and ability of the EDM machine manufacturer to after-sales service, choose China Spark Erosion machine with guaranteed after-sales service, such as Jiangsu Sammlite Machinery Die Sinking EDM Manufacturere.

Sammlite Machinery's EDM Machine Development

Jiangsu Sammlite Machinery was established in 2000. The company has more than 20 years of experience in electrical processing and manufacturing. The company’s main products are CNC Die Sinking EDM, CNC wire cutting machines, and Drill EDM. In addition to having a stable domestic market, the products It is also exported to more than a dozen countries and regions including the United States, Germany, Turkey, Sweden, Japan, South Korea, Australia, Poland, Mexico, Saudi Arabia, Iran, Brazil, South Africa, Colombia, Malaysia, Thailand, India, and Vietnam.