Wire EDM is also known as: Wire cut EDM, Wire cutting Electro Erosion, Wire electrical discharge machining. It uses electrode wires (molybdenum wire, tungsten-molybdenum wire) as the electrode, and the working fluid as the medium. Under the action of the high-frequency pulse power supply, a spark discharge is formed between the tool electrode and the workpiece, and the discharge channel instantly generates high temperature , The surface of the workpiece is melted or even gasified. The wire cutting machine moves through the X/Y axis and the U/V taper axis to make the electrode wire move along the predetermined trajectory, so as to achieve the purpose of processing the workpiece. WEDM are widely used in molds, electronic instruments, precision machinery, auto parts, military industry and other departments. The large taper of the configuration greatly expands the processing range of the wire cutting machine, and is aimed at plastic-steel door and window profile forming molds, aluminum alloy door and window profile forming molds, auto parts, televisions, washing machines and other household appliances shell molds.

Electrical discharge machining (EDM Electro Erosion), also known as spark machining, spark eroding, die sinker. Consisting of an electrode and work piece submerged in an insulating liquid. The electrode and work piece are connected to a suitable power supply. SAMMLITE Die Sinking Machine combining with Japan (SODICK) based advanced system leads to a quality machining. It is mainly used for processing molds and parts with complex shaped holes and cavities; processing various conductive materials, such as cemented carbide and hardened steel, etc.; processing deep and thin holes, special-shaped holes, deep grooves, narrow slits and Cutting thin slices, etc.; processing various forming tools, templates and thread ring gauges and other tools. SAMMLITE spark machine can process the mirror effect. It is the best spark machine today. The processed molds can be directly used in production without saving molds, saving labor and improving efficiency. Moreover, the precision of the mirror sparking machine High, especially in the application of precision molds, the advantages are obvious.

EDM Hole Drilling (hole popping) uses an energized rotating tube as an electrode. Its electric pulse electrode is a hollow copper rod. The working fluid passes through the copper rod hole and discharges with the workpiece to corrode the metal to achieve the purpose of perforation. It is used to process the fine holes of super-hard steel, cemented carbide, copper, aluminum and any conductive material. Small hole EDM drilling is ideal for putting ejector holes in hardened punches, coolant holes in cutting tools, vent holes in molds, and start holes for wire EDM. As a leading EDM machine manufacturer, our machines mainly to solve the processing problems of conductive parts that cannot be solved by traditional processing such as special materials, complex structures, and micro holes. Sammlite Electro Erosion machines are widely used in energy, electronics, medical equipment, molds, automobiles, aviation blades, chemical fiber and other industries

WHY CHOOSE SAMMLITE

One Year Warranty & Lift Time Support Service

Engineering Team Provides 24/7 Services

Scientific Quality Measurements

REAL CASES OF ELECTRO EROSION

Die Sinker machine play a vita role in manufactur automobile moulds

Electrical discharge machine in control panel mold processing

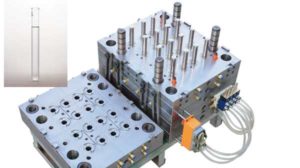

CNC EDM can process medical molds, which are very demanding molds

The connectors produced by the discharge equipment enable engineers to have greater flexibility when designing and integrating new products

Leading Manufacturer Company in EDM TECHNOLOGY

SAMMLITE MACHINERY

LATEST NEWS

EMO Show 2023 Sammlite EDM

EMO SHOW Hannover 2023 SAMMLITE Booth Share on facebook Facebook Share on twitter Twitter Share on linkedin LinkedIn Sammlite Machinery will be participated in EMO

Top 5 Wire Cut Factory In The World

Top 5 Wire Cut Factory In The World Share on facebook Facebook Share on twitter Twitter Share on linkedin LinkedIn Wire Cut machines has been

Can wire cut EDM proecess alloy cutter & PCD material?

Can wire cut EDM proecess alloy cutter & PCD material? Share on facebook Facebook Share on twitter Twitter Share on linkedin LinkedIn Can CNC wire