Home » CNC Electrical Discharge Machine EDM Maintenance

CNC Electrical Discharge Machine EDM Maintenance

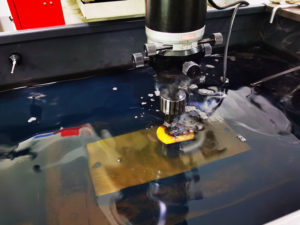

CNC EDM (Computer numerical control Electrical Discharge Machine), CNC EDM is computer numerical control EDM, which realizes multi-axis linkage machining. CNC EDM realizes automatic control through computer to complete complex and precise electrical sparking process. In the actual machining process, the computer sends out commands to control the EDM according to the input program to realize single-axis or multi-axis CNC machining.

Electrical Discharge Machine Inspection and maintenance

Daily Inspection and Maintenance of Die sinking EDM

1: Clean the dirt on the CNC EDM machine tool and guide rails every day to keep the EDM machine clean, and turn off the air source and power supply when off work.

2: If you leave the machine for a long time, turn off the power to prevent non-professional operation.

3: Pay attention to observe whether there is lubricating oil on the surface of the machine’s horizontal and longitudinal guide rails and racks to keep them well lubricated.

Weekly Inspection and Maintenance of Die sinking EDM

1: The electrical discharge machine should be thoroughly cleaned every week, the horizontal and vertical guide rails, the transmission gear racks should be cleaned, and the lubricating oil should be filled.

2: Check whether the horizontal and vertical rail wipers work normally, if not, replace them in time.

3: If there is an automatic height adjustment device, check whether it is sensitive and whether to replace the probe.

Monthly Inspection and Maintenance of Die sinking EDM

1: Check whether there is garbage at the gas port of the electrical dischage machine, and whether each valve and pressure gauge work normally.

2: Check whether all trachea joints are loose and all pipes are not damaged. Tighten or replace as necessary.

3: Check whether all transmission parts of CNC Die sinking EDM are loose, check the meshing of gears and racks, and adjust if necessary.

4: Loosen the tightening device and push it by hand to see if it can come and go freely. If there is an abnormal situation, adjust or replace it in time.

5: Check the clamping block, steel belt and guide wheel for looseness and tightness of the steel belt, and adjust if necessary.

6: Check the strong EDM generator and operating platform, whether the fastening screws and thread ends are loose, and clean the dust in the cabinet.

7: Check the performance of the buttons and selector switches, replace the damaged ones, and finally comprehensively inspect the drawing pattern inspection and the machine accuracy inspection.

8: Die Sinking EDM during sparking process, the average value of local and instantaneous explosive force is very small, which is not enough to cause deformation and displacement of the workpiece