Home » Wire Cutting EDM Machine Regular Maintenance

Which Parts of The Wire Cutting EDM Machine Need Regular Maintenance?

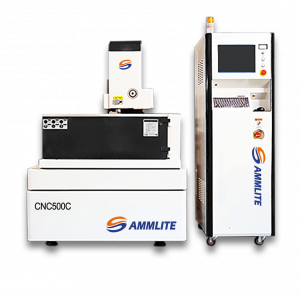

The daily maintenance and maintenance of Jiangsu Sammlite Machinery WEDM Factory’s Wire Cutting EDM machine is very important, which is related to the service life of the machine tool. In addition to daily maintenance, users should also pay attention to regular maintenance to prevent the expansion of small problems and affect the normal use of the machine tool. When overhauling, the focus should be on the following four parts:

1. Wire Cutting EDM Power supply:

Check the incoming power supply of the Wire Cutting EDM Machine, whether the voltage fluctuation is within the range of ±10%, whether the high-order harmonics are serious, the size of the power, whether a regulated power supply needs to be installed, etc.

2. Molybden Wire Cutting EDM working fluid:

The functions of the wire cutting working fluid are cooling, washing, chip removal, etc. Therefore, whether the wire cutting working fluid is qualified or not is directly related to the quality of the workpiece after processing. Check whether the wire cutting fluid is too dark and has peculiar smell. If there is such phenomenon, its comprehensive performance will be deteriorated, which will easily lead to wire breakage.

3. Electrode molybdenum wire:

The quality, installation, preservation and other factors of the electrode wire are directly related to the quality of the workpiece after processing. Check whether the electrode wire is properly selected. When processing thick workpieces, a thicker electrode wire should be used, which is conducive to chip removal and its tension; check the tightness of the electrode wire installation. If it is too tight, the internal stress will increase, and it is easy to break the wire; check whether the installation position of the electrode wire deviates from the center and whether it is not in the same plane. , If there is moisture, oxidation and exposure during storage, the electrode wire will also become brittle and easy to break.

4. Wire Cutting EDM Control cabinet:

Due to static electricity and other reasons, dust is easy to accumulate in the control cabinet. When these dusts are damp, they will corrode the circuit board, cause short circuit or open circuit, and then damage the electronic components, and even cause the entire circuit board to be scrapped. Therefore, it must be checked regularly.